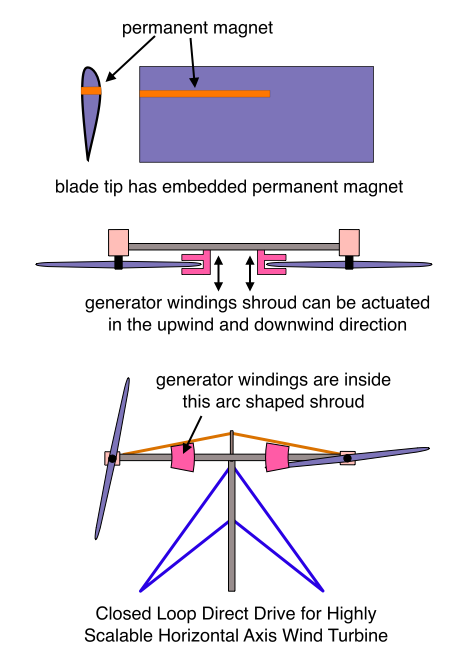

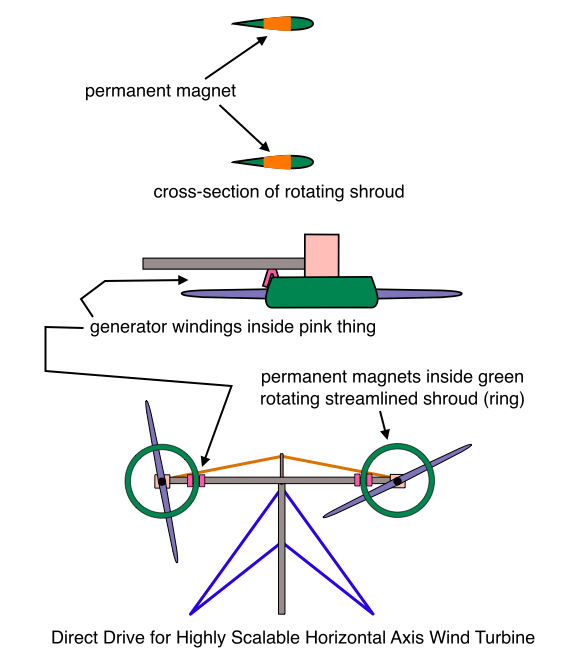

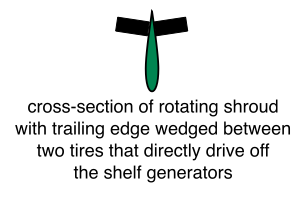

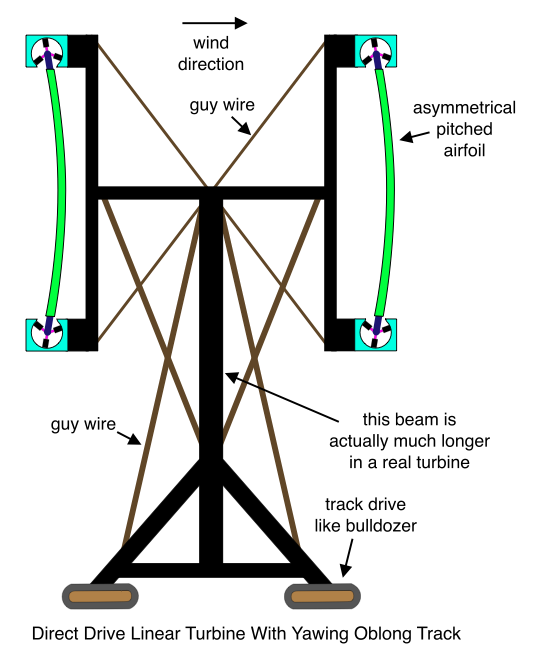

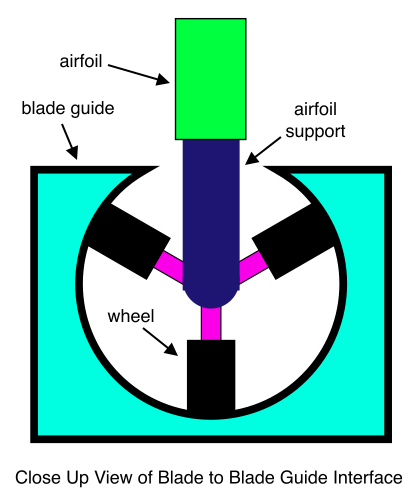

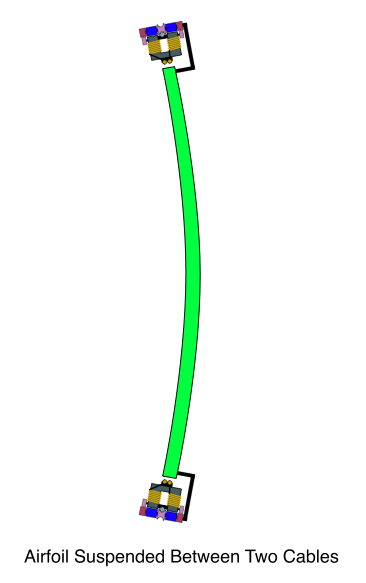

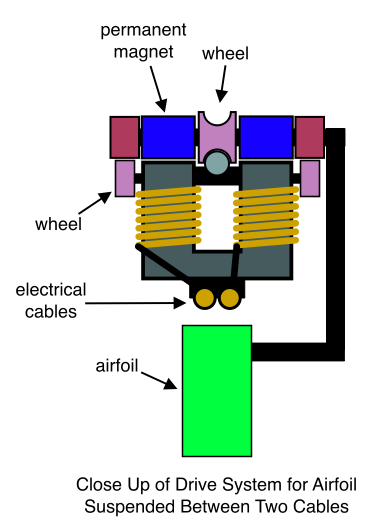

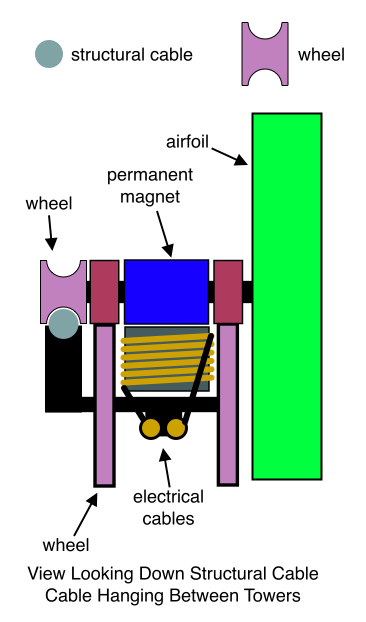

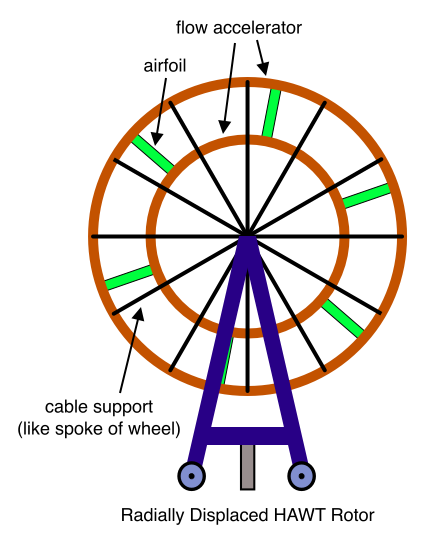

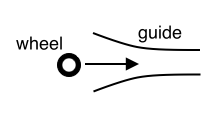

A number of posts to this blog describe turbines (both HAWTs and VAWTs) having blades that are supported at the high-speed blade tips rather than at the low speed parts of the blades. This is usually accomplished by having a blade tip engage some sort of slot that is cut into a blade guiding track, so that the action is somewhat reminiscent of the way a rail guides the wheel of a train. One of the biggest problems with this approach is how to come up with a simple, reliable way of converting the kinetic energy of the blades to electricity. The conversion apparatus should not be unweildy or cumbersome, and should not require too much hardware. (For example, in some of my earlier posts I have suggested distributing generator windings all along a very lenghty blade guiding track. This is clearly undesirable because it would make the tracks very heavy and very expensive.)

I think I may have stumbled on a good way to deal with this problem just a minute ago while writing the post entitled: Skyscraper with H-Rotors. I didn’t do a very good job of describing the counter-rotating drive idea in that post, so I’ll attempt to do a better job of it here. (Although the technique described here may be applied to many of the HAWT and VAWT turbines proposed on the Salient White Elephant, you might want to read Skyscraper with H-Rotors first, since I’ll draw the diagrams and everything assuming that we’re applying the counter-rotating direct drive idea to that particular turbine.)

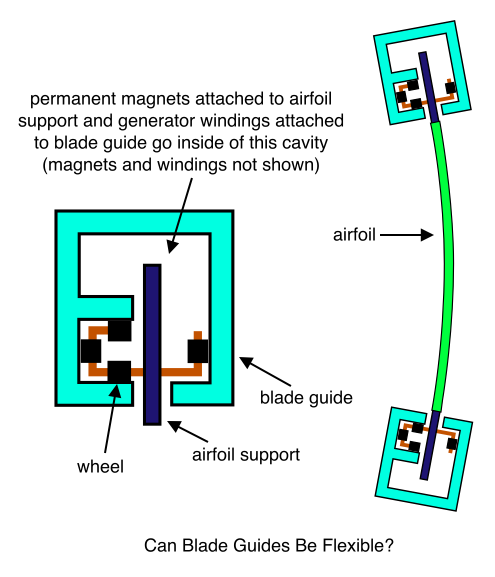

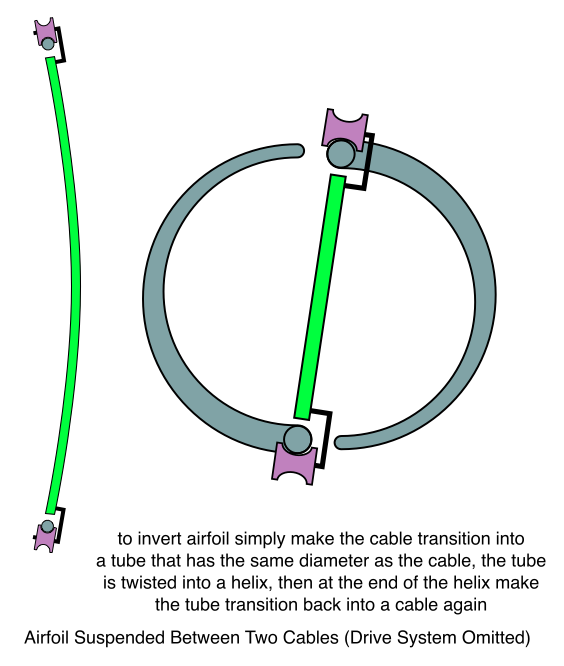

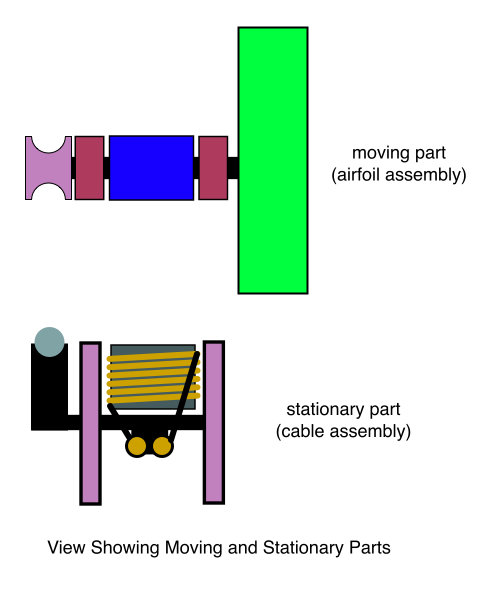

This turbine produces power in pulses. Each time two blades that are traveling in opposite directions pass each other, their generator components (permanent magnets and coils) pass close to each other as well. So a pulse of power is produced when two blades pass each other. Obviously, it would be better for a turbine to produce power at a smooth constant rate. This is desirable for many reasons. For one thing, producing power in pulses applies a cyclic fatigueing load on the mechanical components, and this is obviously bad news. For another, the electricity is easier to process and manipulate if it is produced at a smooth regular rate. But I am hypothesizing that the design proposed here may be a good one because it allows blades to be supported at both blade tips, even as both tips travel at high velocity! This is a tremendous advantage. But the main advantage of this design is that although it allows blades to travel long distances guided only by slots that are cut into blade guides, it does not require for these long distances to have generator components (magnets and/or coils) distributed along these long portions of the blade guides. Instead, the generator components are compact, and are attached to the ends of the airfoils. You can think of all of the airfoils that rotate (say) clockwise as comprising the generator “stator”, while all of those rotating counter-clockwise comprise the generator rotor. Of course, another disadvantage of this approach is that slip rings would be required to get the power away from the blades and into the electrical system. But there’s another advantage as well – the fact that the generator’s rotor and “stator” rotate with equal and opposite rpm’s effectively doubles the relative speed with which the coils and magnets pass each other.

This turbine produces power in pulses. Each time two blades that are traveling in opposite directions pass each other, their generator components (permanent magnets and coils) pass close to each other as well. So a pulse of power is produced when two blades pass each other. Obviously, it would be better for a turbine to produce power at a smooth constant rate. This is desirable for many reasons. For one thing, producing power in pulses applies a cyclic fatigueing load on the mechanical components, and this is obviously bad news. For another, the electricity is easier to process and manipulate if it is produced at a smooth regular rate. But I am hypothesizing that the design proposed here may be a good one because it allows blades to be supported at both blade tips, even as both tips travel at high velocity! This is a tremendous advantage. But the main advantage of this design is that although it allows blades to travel long distances guided only by slots that are cut into blade guides, it does not require for these long distances to have generator components (magnets and/or coils) distributed along these long portions of the blade guides. Instead, the generator components are compact, and are attached to the ends of the airfoils. You can think of all of the airfoils that rotate (say) clockwise as comprising the generator “stator”, while all of those rotating counter-clockwise comprise the generator rotor. Of course, another disadvantage of this approach is that slip rings would be required to get the power away from the blades and into the electrical system. But there’s another advantage as well – the fact that the generator’s rotor and “stator” rotate with equal and opposite rpm’s effectively doubles the relative speed with which the coils and magnets pass each other.

So before closing, let me address one of the biggest disadvantages of the idea proposed here – that power is produced in pulses. First of all, the fact that generator rotor and “stator” components are counter-rotating means that more pulses per second are produced than you might otherwise expect. (The more pulses the better. If we had enough pulses then they’d all bunch together and we’d have continuous power. As a matter of fact, three phase power is produced in pulses as well, yet these pulses combine to produce power that is perfectly constant. Might we find a way to exploit this three phase effect to make the power output from this machine constant? Don’t know, and too tired to think about it right now, so maybe I’ll revisit this later. But anyway it may not matter. I’m not concerned about the electrical pulsing – we can easily deal with that using power electronics. I’m more concerned about the pulsating mechanical loads, because these will fatique mechanical components and cause them to fail. On the other hand, the good news is that this pulsating load is confinded with a small space that is enclosed by the slots that guide the blades. This is good, because the more confined it is, the more options we have for dealing with the cyclic load. One option being, for example, just beefing up the support structure in that area. This is possible because, again, this area is aerodynamically shielded from the outside wind because it lives inside the slot.) Anyway, as I said, the because the blades are counter-rotating, they pass each other at a relatively high frequency. So maybe we can just design the machine to have many small blades (i.e. many blades, each having a short chord). Now when all these blades counter-rotate, we may end up with so many pulses that the output power looks like DC with a ripple on top. (Remember that adjacent blades don’t necessarily need to be separated by a constant angle. For example, just because there are (say) 6 blades that rotate (say) clockwise doesn’t mean that each adjacent blade must be separated by an angle of 360/6 = 60 degrees.)

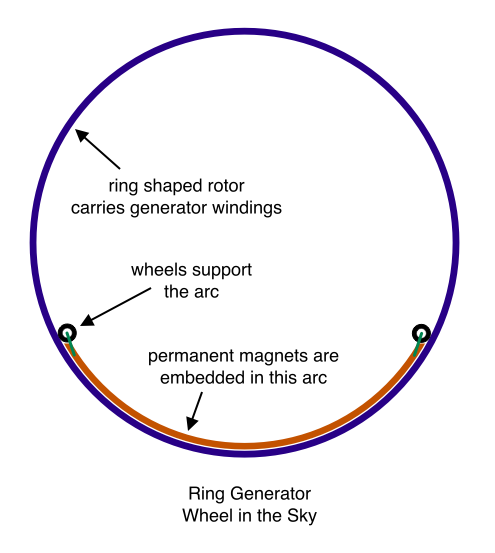

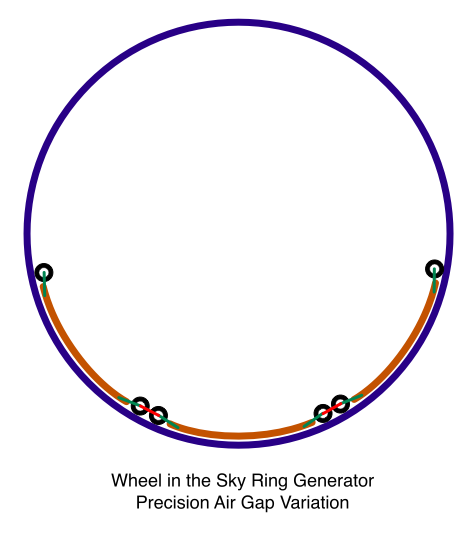

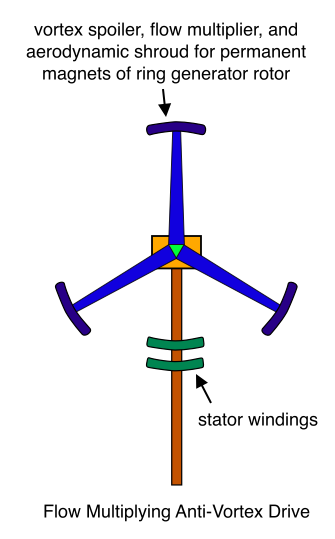

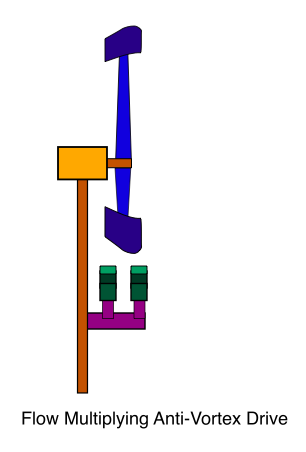

Ring Generator Option

If the pulsating loads turn out to be a showstopper, then we can always fall back on the ol’ ring generator approach. In this case, we have the advantage that the rings are counter-rotating, thus doubling the velocity between magnets and coils.