Since there are currently 127 posts on the Salient White Elephant, I thought it might be a good idea to devote this post to summarizing the best of these ideas.

Big Wind or Small Wind?

A worldwide network of inexpensive desktop computers ultimately proved to be far more powerful than the super computer. This lesson should not be lost on wind enthusiasts. However, the Salient White Elephant has proposed intriguing ideas both for very large wind turbines as well as for small wind turbines that may be deployed in large numbers. So why not experiment with both, and let the market sort the winners from the losers?

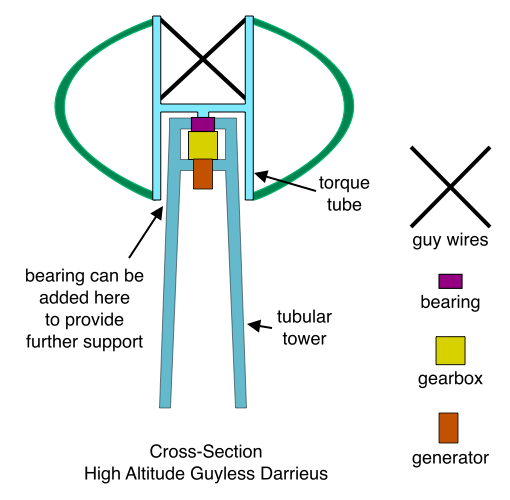

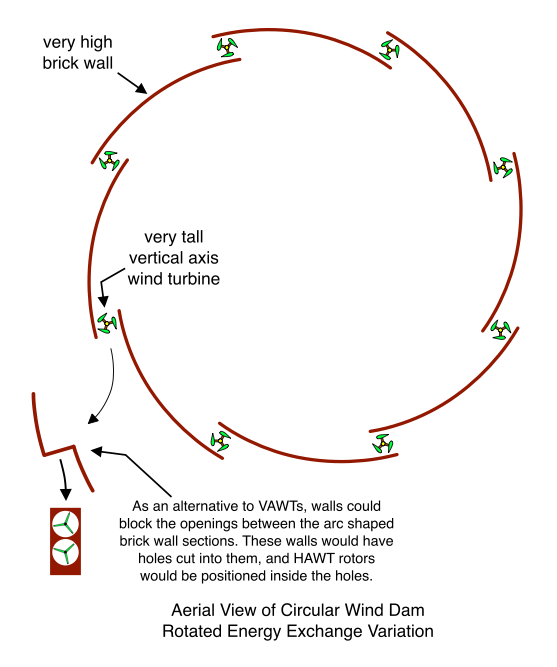

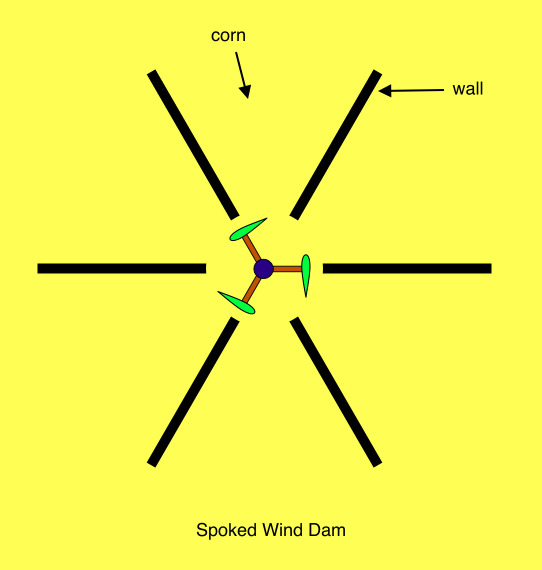

Idea #1) Circular Wind Dam

Advantage Over Flow Concentrators and Diffusers

Increasing the outer diameter of a shroud in order to squeeze more wind through a turbine rotor causes the wind to develop greater tendency to veer around the entire structure – shroud, rotor, and all. For this reason, the laws of fluid mechanics tell us that you can squash only a limited amount of “extra wind” through the small opening that contains the rotor. But the wind dam is not subject to this limitation. Why not? Because the purpose of its flow manipulating structure is not to “contain the wind”, but rather to force it to do what it already wants to do – to veer around the entire flow manipulating structure! This effect can be increased indefinitely by building larger and larger dams. In this case, having nowhere else to go, the wind is obliged to flow around the entire structure, regardless of how big it is!

Another obvious advantage of the wind dam is that it is stationary and attached to the earth. A concentrator or diffuser must be suspended high in the air, and must be yawed with the machine. The shroud is large, poorly supported, and vulnerable to mechanical failure.

Here’s a link to the original Circular Wind Dam post. (I wonder if an offshore version of this idea would be possible in shallow water. In this case, the underwater part produces hydro power and the above water part produces wind power. One nice thing about combining the hydro and wind is that it would probably increase the net capacity factor. Also, it seems like it might be possible to design the underwater part to harvest both tidal and wave power.)

Idea #2) High Capacity Factor Wind Turbine

A very large wind turbine with a flow accelerating component (like the Circular Wind Dam just described) is designed to have a very low cut-in wind speed. The turbine is also designed to be very inexpensive through the removal of weight, leaving it perhaps even flimsy. Structural integrity is achieved by providing the machine with ample means for shedding the energy of higher speed winds, and for allowing storm winds to pass through the structure virtually unimpeded. (Perhaps a wall has slats or portholes that can open and close.)

Now because of the flow amplifying nature of the machine, it should be able to produce a significant amount of power at low wind speeds. This feature is remarkable in that it directly and significantly addresses the most glaring deficiency of wind as an energy source – it’s low capacity factor. I discussed increased capacity factor in two earlier posts entitled Capacity Factor and Very High Capacity Factor Wind Turbine.

Idea #3) Small Wind Business Model

This company (Small Wind Inc.) installs small wind turbines into people’s back yards, or perhaps onto the roofs of their homes or small businesses. However, Small Wind Inc. uses exactly the same business model as does the type of company that owns, maintains, and operates utility scale wind farms. That is, Small Wind Inc. erects, maintains, and repairs all of its wind turbines, and it sells the electricity generated by these small wind turbines to the power company. In exchange for the use of the home owner’s property, roof top, electrical wiring, wind resources, and so on, the homeowner receives a monthly check from Small Wind Inc.

Advantages of the Small Wind Business Model

- Because Small Wind Inc. has tens of thousands of turbines in the field, it is in an excellent position to negotiate contracts with the power company. For example, it may have the negotiating firepower to be financially rewarded for the benefits of producing power at or near the point of consumption (instead of wasting energy by transmitting it over long distances through high voltage transmission lines).

- Convincing a homeowner to put a big chunk of her life savings into an investment that is difficult to understand is a hard sell. Convincing a homeowner to climb an 80 foot tower with a pipe wrench clinched in her teeth to repair a broken wind machine is even more difficult. But it’s easy to sell someone on the idea of getting a monthly check when their only contribution is to avoid hitting base of the tower with a lawnmower!

- Small wind machines are often considered more attractive than large wind farms. This allows small machines to be deployed in very large numbers. Coupled with the increased efficiency of generating power near the point of consumption, the small wind business model is good energy policy. The distributed nature of small wind also means that only small fractions of capacity will be offline at any given time for maintenance or repair.

- Small Wind Inc. has experts in turbine siting. Only those homes and businesses that happen to have a good wind resource are selected as customers.

- If 4 out of 10 homes in a small community have good wind resources, then the whole community can run on green power. Simply install 10 wind turbines on the 4 properties that have good wind resources.

- Because Small Wind Inc.’s technicians are experts, cost of maintenance and repair of the wind machines is low.

- Since Small Wind Inc.’s turbines may be deployed in large numbers, costs are lowered through purchasing parts and services in bulk, and economies of scale are realized in a variety of predictable and unpredictable ways.

- Because power is produced at the point of consumption, transformers are not required to step voltage up to transmission line levels. This delivers significant cost savings.

- Financing costs are low due to the expertise Small Wind Inc. has in this area, economies of scale, and the size, scrutability, and stability Small Wind Inc.

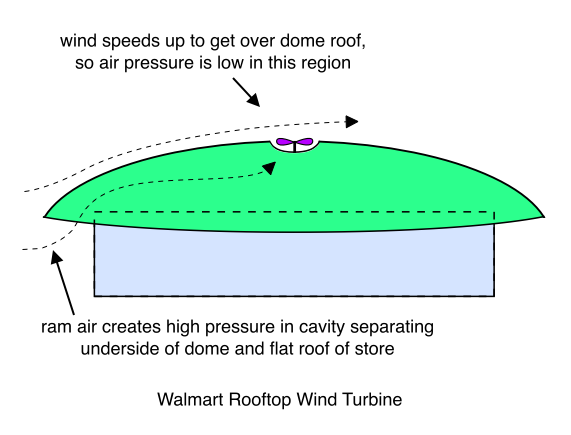

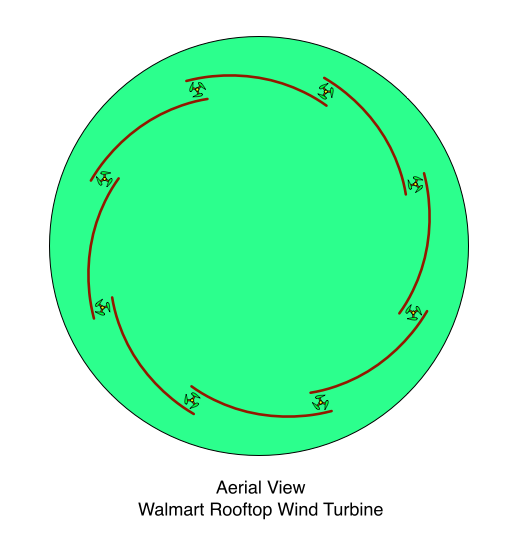

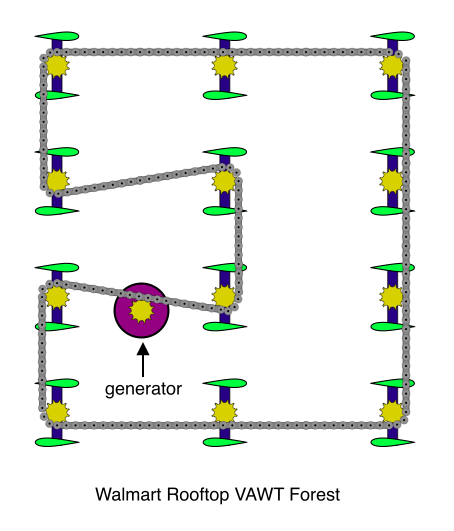

Idea #4) Walmart Rooftop Wind Turbine

Though not shown in the diagram above, slats are positioned in the gap between the edge of the flat top of the Walmart building (dotted line) and the bottom of the dome roof. (This is the gap through which the ram air flows in under the dome roof.) The slats can open and close to allow or block this flow. With the wind direction depicted above, all of the slats on the left hand side of the diagram would be open in order to allow the ram air to enter from the left and concentrate beneath the dome, and all of the slats on the right hand side would be closed to prevent its escape. The original post describing this idea, Venturi Dome Baseball Stadium, has a diagram that shows how the slats work. Another post, Rooftop Wind Turbine, described a rooftop turbine for a typical residence.

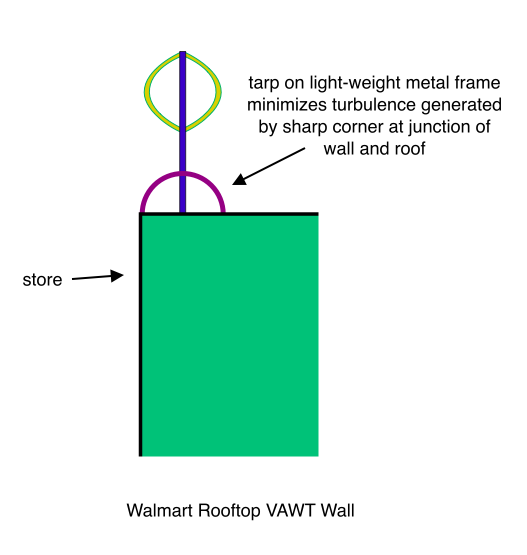

Idea #5) Another Walmart Rooftop Wind Turbine

Simply put a Circular Wind Dam onto the roof of a Walmart store. In order to reduce turbulence, the store is first provided with a dome-shaped roof, and the Circular Wind Dam is mounted on top of the dome. The dome would look a little like the dome in the Walmart rooftop turbine described previously, but it would not have a hole and a turbine rotor in its center. Also, there would be no slats or gap between the edges of the flat top of the store and the underside of the dome.

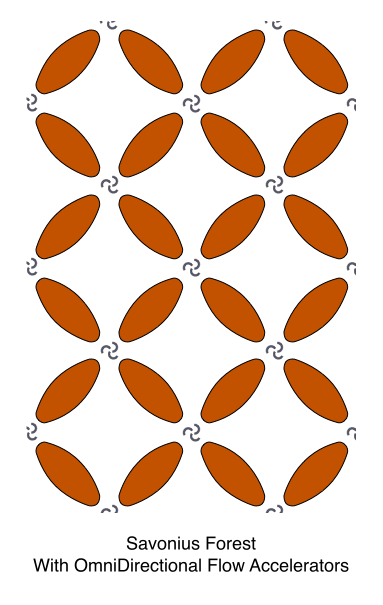

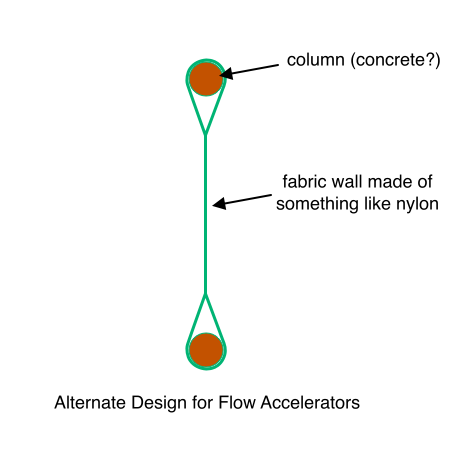

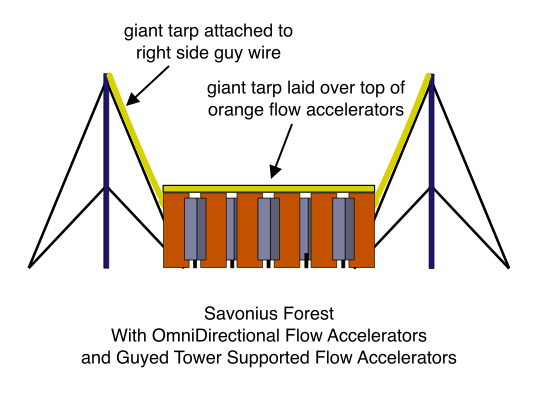

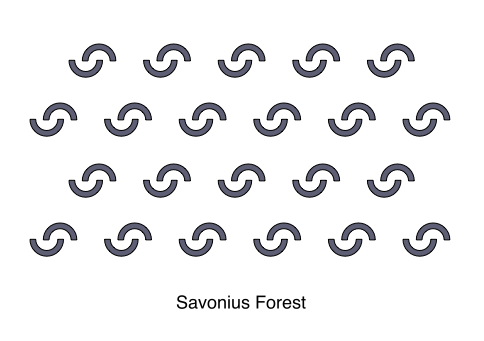

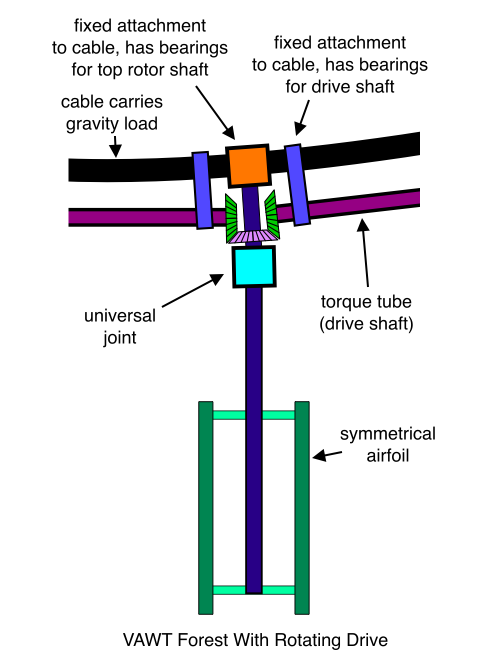

Idea #6) VAWT Forest With OmniDirectional Flow Accelerators

Here’s the original post: VAWT Forest With OmniDirectional Flow Accelerators.

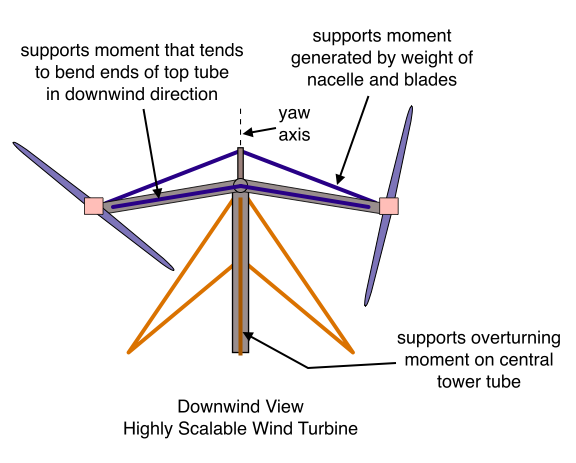

Idea #7) Highly Scalable Horizontal Axis Wind Turbine

In the diagrams below, the orange and dark blue lines represent guy wires. Comments are provided that explain which load each guy wire supports.

The Highly Scalable Horizontal Axis Wind Turbine is remarkable in that guy wires assist in supporting all of the large tower loads that are carried by the machine. This allows a great deal of weight and cost to be removed from the design. The original post explains in detail, and includes some very cool tilt-down versions.

The Highly Scalable Horizontal Axis Wind Turbine is remarkable in that guy wires assist in supporting all of the large tower loads that are carried by the machine. This allows a great deal of weight and cost to be removed from the design. The original post explains in detail, and includes some very cool tilt-down versions.

Idea #8) Automatic Wind Turbine Blade Washer

If you don’t believe this embarrassingly simple device will work, then read the original post. You’ll be amazed that none of us ever thought of this idea until now.

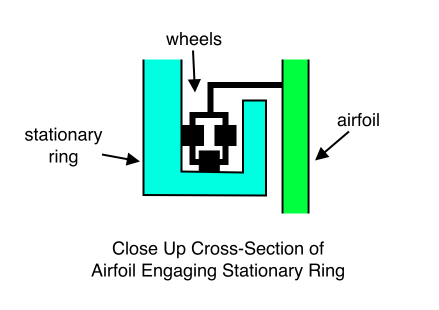

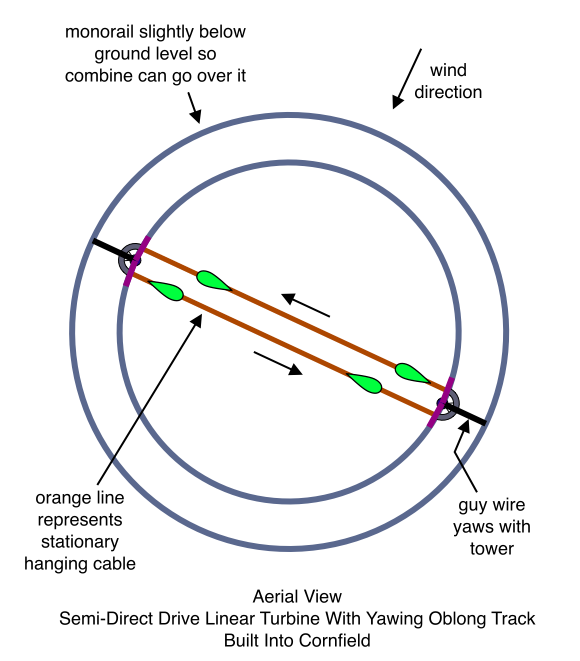

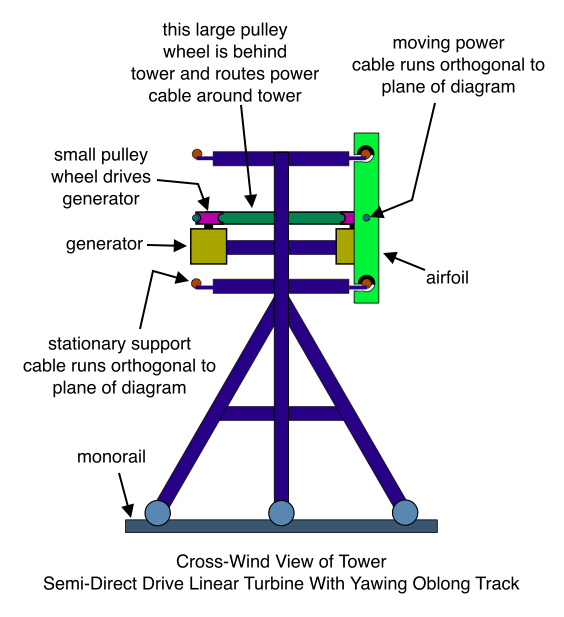

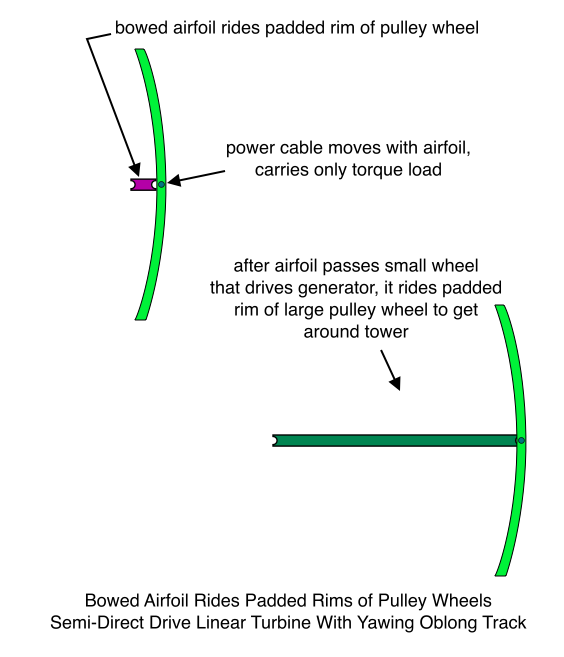

Idea #9) Semi-Direct Drive Linear Turbine With Yawing Oblong Track

This one is too complicated to summarize, so I’ll just post a link to the original post that described it. But first, a word of advice – don’t be fooled by the apparent complexity of the diagrams. It isn’t as complicated as it first appears, and offers some tremendous performance advantages: Semi-Direct Drive Linear Turbine With Yawing Oblong Track.

More Good Ideas

Here’s a link to a page that is full of links to the best posts on the Salient White Elephant. That page has more links than are included the current post. Or if you’re really a glutton for punishment, you could just read every single one of the 127 Salient White Elephant posts!

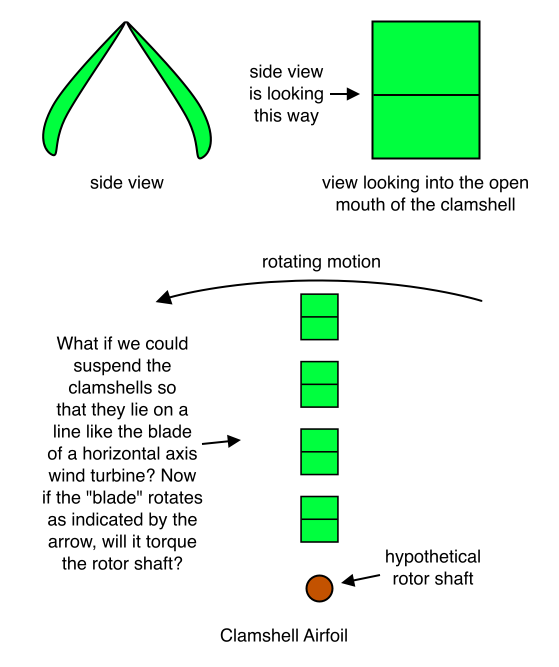

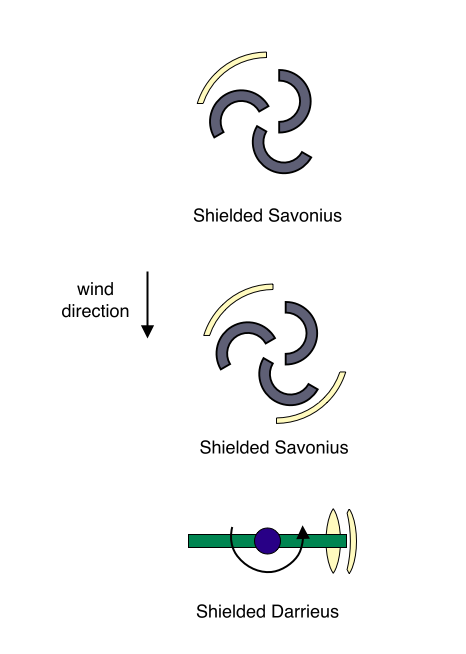

You may have heard that wind turbines with lifting devices are far more efficient than those that rely on drag forces alone. I can think of two ways of looking at this. First, the lifting force created by suction on the low pressure side of the airfoil is much larger than the lifting force created by ram air pressure on the other side. I read once that the suction force is 5 times greater than the ram air force. Second, most drag devices create turbulence. Why is this bad? Imagine the long line of air molecules “dancing the train” past the high-speed airfoil rotor. Their momentum is in the downstream direction, and their motion is very orderly. It’s hard for a molecule to make its way back toward the rotor because everybody is moving downstream. It’s kind of like trying to drive slow on a Los Angeles freeway when everybody else is barreling by at 90 mph. But turbulence is disordered motion. Imagine a crowd of people in a riot. Everybody’s running this way and that, banging into each other and so on. Now imagine the air molecules passing a turbine rotor in this chaotic fashion. Not only is it easier to make your way back to the rotor, but in fact somebody may bang into you and push you back toward the rotor. For this reason, the rotor cannot maintain low pressure on its downwind side. This eliminates the suction force that the rotor might otherwise generate, and therefore there is far less force to torque the rotor against the generator and generate electricity. Of course, we didn’t need to go through all this analysis to realize that the drag rotor turns less of the wind’s kinetic energy into electricity. All we had to do is consider all the chaotic energy in the “wind riot” that is left in the wake of the rotor. All of this chaotic energy is energy that was not converted into electricity, and it therefore represents an inefficiency in the system. We’d like to design a rotor that slows all of the air gently and evenly, leaving the least amount of disturbance in the wake.

You may have heard that wind turbines with lifting devices are far more efficient than those that rely on drag forces alone. I can think of two ways of looking at this. First, the lifting force created by suction on the low pressure side of the airfoil is much larger than the lifting force created by ram air pressure on the other side. I read once that the suction force is 5 times greater than the ram air force. Second, most drag devices create turbulence. Why is this bad? Imagine the long line of air molecules “dancing the train” past the high-speed airfoil rotor. Their momentum is in the downstream direction, and their motion is very orderly. It’s hard for a molecule to make its way back toward the rotor because everybody is moving downstream. It’s kind of like trying to drive slow on a Los Angeles freeway when everybody else is barreling by at 90 mph. But turbulence is disordered motion. Imagine a crowd of people in a riot. Everybody’s running this way and that, banging into each other and so on. Now imagine the air molecules passing a turbine rotor in this chaotic fashion. Not only is it easier to make your way back to the rotor, but in fact somebody may bang into you and push you back toward the rotor. For this reason, the rotor cannot maintain low pressure on its downwind side. This eliminates the suction force that the rotor might otherwise generate, and therefore there is far less force to torque the rotor against the generator and generate electricity. Of course, we didn’t need to go through all this analysis to realize that the drag rotor turns less of the wind’s kinetic energy into electricity. All we had to do is consider all the chaotic energy in the “wind riot” that is left in the wake of the rotor. All of this chaotic energy is energy that was not converted into electricity, and it therefore represents an inefficiency in the system. We’d like to design a rotor that slows all of the air gently and evenly, leaving the least amount of disturbance in the wake.